UNIVERSAL TEST BENCH FOR COMMON RAIL SYSTEMS, EUP, EUI AND HEUI

With more than ten years of experience in developing test equipment, we did not simply improve our test benches – we significantly redesigned them to ensure maximum efficiency and comfort of use.

Resting on deep knowledge and innovative approaches, we present ONYX-I4 — a product that synthesizes decade of engineering knowledge and our passion for improvement.

This stand was created to perform the most demanding tasks of modern diesel service.

Dimensions without monitor (WxDxH)

1160 x 690 x 1530 mm

Dimensions with monitor, Maximum (WxDxH)

1620 x 690 x 1870 mm

Peso

450 kg Net

Fornecimento de energia

380V 50/60 Hz, 3 fases

Maximum Current

16А

Potência motora

5,5 kW, controlled by inverter

Maximum motor rotation

1500 rpm

Máxima alta pressão

2800 bar

Automatic pressure control for injector backleak

-0,3 – 12 bar

Pressão de fornecimento

0 - 6 bar

Tanque de óleo de teste

30 l

Measured injector delivery volume

0,3 – 830 cm3/min

I-Art pressure sensors and rail pressure sensors testing

EASY ACCESS. The new protective cover opening mechanism greatly simplifies access to the work area.

ERGONOMICS. The height of the monitor is easily adjustable, which reduces fatigue during long hours of work.

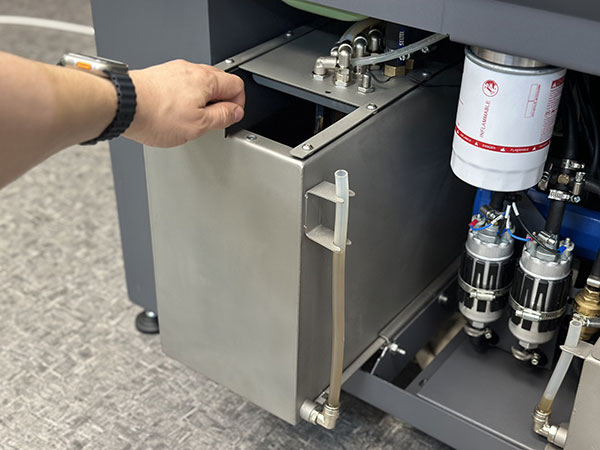

FAST SERVICE. Sliding test oil tank, to simplify its maintenance, all important components, such as filters are easily accessible

Every hydraulic connection to the test bench is protected by a filter with easy access.

ORGANIZED WORKPLACE. A separate practical drawer for quick access to store frequently used tools and accessories. Additional drawer for keyboard and mouse ensure perfect order and the safety of equipment during wet work.

QUICK-CONNECTING INJECTORS. Due to improved design now connecting injectors takes less time and does not need any additional hydraulic and mechanical accessories besides adapters.

AUTOMATIC SUPPORT CONTROL. Injectors backleak discharge and pressurized backleak discharge is now controlled automatically within the test bench eliminating the need for costly additional valves and constant control and maintenance of their condition.

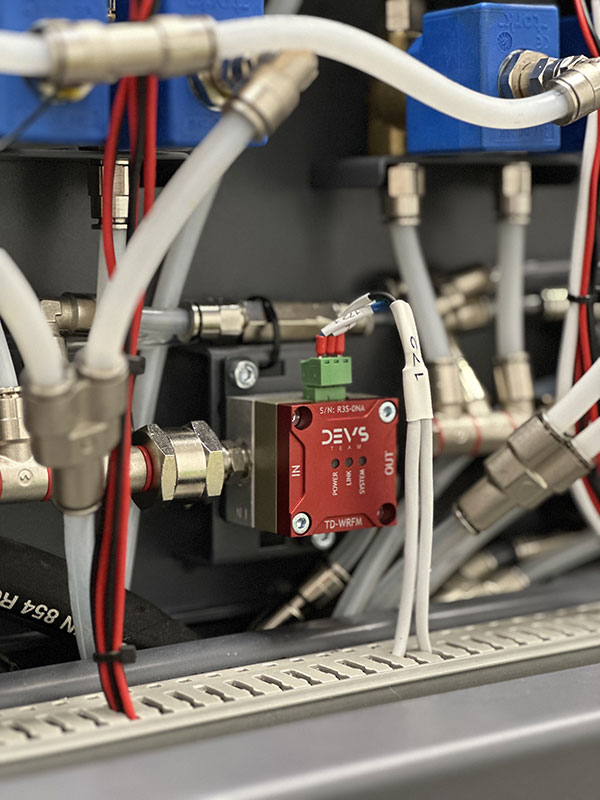

TURBO SPEED MEASUREMENT AND CODING. Thanks to our reengineered flowmeter now injectors measurement and coding is up to two times faster. New flowmeter has the three times wider hydraulic measurement range and three times faster measurement capability.

HIGH STABILITY. Redesigned large volume rail provides ideal stabilization of pressure and temperature over the test oil which improves reliability and repeatability of measurement results.

CALIBRATION ACCURACY. Flow meter with temperature and volume correction guarantees quality measurements under any conditions. All peripheral sensors also have pre-programmed calibration parameters

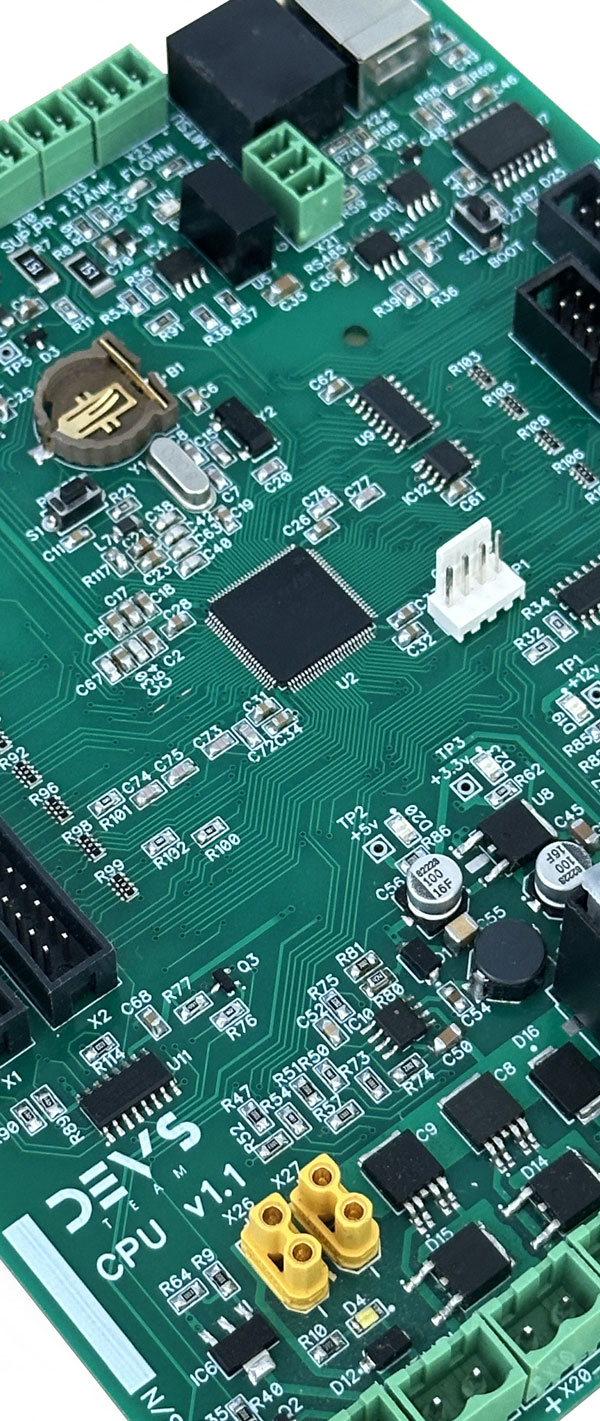

MODERN SYSTEM MANAGEMENT. Our state-of-the-art control system architecture uses advanced technologies to improve signal accuracy and measurement speed. This reduces test time and improves overall equipment performance, which is critical for today’s diesel service.

EFFICIENT COOLING. New freon-free cooling system with electronic control ensures the stable temperature of the test liquid. This system minimizes the risk of deviations in test results due to temperature fluctuations, improving the control of the testing process.

SELF-DIAGNOSTICS. In ONYX platform new peripheral systems selfmonitoring function simplifies maintenance and technical support processes.

MEASUREMENT AND CONTROL. An inbuilt system for measuring electrical parameters, such as resistance, short circuit to body, capacitance and inductance of injectors, provides accurate diagnostics of the state of the actuators of tested components.

ADVANCED INJECTOR CONTROL. Updated injection delay and response time controls allows for accurate coding of modern injector systems such as the Delphi F2P, F2E, and Continental PCRs5. CONTROL profile charge piezo nozzle according to with requirements manufacturers ensure compliance with all technical specifications.

TWO-CHANNEL INJECTOR CONTROLLER. Four completely independent signal channels allow full testing and coding of various types of injectors, including СРIN 4.2 and Delphi E3, F2E, F2P pump-injectors.

SENSOR PROCESSING. Advanced VCC and NCC measurement capabilities for the new Bosch CRI 3-25 and CRI 3-27 systems, as well as accurate pressure measurement for the I-ART systems, provide a foundation for working with modern diesel systems.

Tell us a few details — our team will get back to you shortly.